Using robotic evolution, UC San Diego scientists trained bacteria to produce more of the pigment that powers octopus camouflage.

Genetic analysis revealed key mutations that turned the microbes into highly efficient pigment factories.

Cracking Nature’s Camouflage Secret

Researchers at the University of California, San Diego, have taken a major step toward understanding one of nature’s most remarkable talents: the ability to disappear in plain sight.

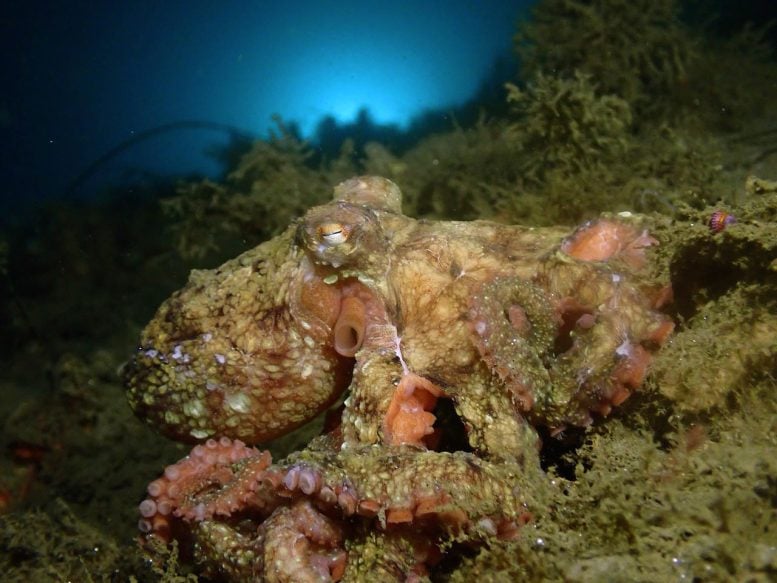

Octopuses, squids, cuttlefish, and their cephalopod relatives are famous for their incredible camouflage skills, rapidly shifting the color and texture of their skin to blend with their surroundings. This natural trick depends on a complex pigment called xanthommatin, which controls many of the animals’ color changes.

For decades, scientists and even defense researchers have been fascinated by xanthommatin’s color-shifting potential. However, reproducing the pigment in a laboratory has proven extremely difficult — until now.

Producing Nature’s Camouflage Pigment at Scale

In a new study, a team from UC San Diego’s Scripps Institution of Oceanography reports a major advance in understanding how nature creates camouflage. The researchers developed a new way to produce xanthommatin in large quantities, making it possible to study and use this elusive pigment more easily than ever before.

Their bio-inspired method generated the pigment inside bacteria, achieving yields up to 1,000 times higher than previous approaches. This breakthrough could enable a range of applications, from sustainable dyes and UV-blocking materials to advanced coatings and photoelectronic devices.

Engineering Bacteria to Make Cephalopod Pigment

“We’ve developed a new technique that has sped up our capabilities to make a material, in this case xanthommatin, in a bacterium for the first time,” said Bradley Moore, the study’s senior author and a marine chemist with joint appointments at Scripps Oceanography and UC San Diego Skaggs School of Pharmacy and Pharmaceutical Sciences. “This natural pigment is what gives an octopus or a squid its ability to camouflage — a fantastic superpower — and our achievement to advance production of this material is just the tip of the iceberg.”

Published on November 3 in Nature Biotechnology, the research was supported by the National Institutes of Health, the Office of Naval Research, the Swiss National Science Foundation, and the Novo Nordisk Foundation.

According to the authors, this discovery does more than explain the chemistry behind nature’s color-changing wonders. The same biotechnology could be applied to other useful compounds, helping industries shift away from petroleum-based production and toward sustainable, nature-derived materials.

From Octopus Ink to Butterfly Wings

Beyond cephalopods, xanthommatin is also found in insects within the arthropod group, contributing to the brilliant orange and yellow hues of monarch butterfly wings and the bright reds seen in dragonfly bodies and fly eyes.

Despite xanthommatin’s fantastic color properties, it is poorly understood due to a persistent supply challenge. Harvesting the pigment from animals isn’t scalable or efficient, and traditional lab methods are labor intensive, reliant on chemical synthesis that is low yielding.

Researchers in the Moore Lab at Scripps Oceanography sought to change that, working with colleagues across UC San Diego and at the Novo Nordisk Foundation Center for Biosustainability in Denmark to design a solution, a sort of growth feedback loop they call “growth coupled biosynthesis.”

Tricking Bacteria Into Creating Camouflage Chemistry

The way in which they bioengineered the octopus pigment, a chemical, in a bacterium represents a novel departure from typical biotechnological approaches. Their approach intimately connected the production of the pigment with the survival of the bacterium that made it.

“We needed a whole new approach to address this problem,” said Leah Bushin, lead author of the study, now a faculty member at Stanford University and formerly a postdoctoral researcher in the Moore Lab at Scripps Oceanography, where her work was conducted. “Essentially, we came up with a way to trick the bacteria into making more of the material that we needed.”

Typically, when researchers try to get a microbe to produce a foreign compound, it creates a major metabolic burden. Without significant genetic manipulation, the microbe resists diverting its essential resources to produce something unfamiliar.

Linking Life to Pigment Production

By linking the cell’s survival to the production of their target compound, the team was able to trick the microbe into creating xanthommatin. To do this, they started with a genetically engineered “sick” cell, one that could only survive if it produced both the desired pigment, along with a second chemical called formic acid

“We made it such that activity through this pathway, of making the compound of interest, is absolutely essential for life. If the organism doesn’t make xanthommatin, it won’t grow,” said Bushin.

Bioengineering Meets Evolution

To further enhance the cells’ ability to produce the pigment, the team used robots to evolve and optimize the engineered microbes through two high-throughput adaptive laboratory evolution campaigns, which were developed by the lab of study co-author Adam Feist, professor in the Shu Chien-Gene Lay Department of Bioengineering at the UC San Diego Jacobs School of Engineering and senior scientist at the Novo Nordisk Foundation Center for Biosustainability. The team also applied custom bioinformatics tools from the Feist Lab to identify key genetic mutations that boosted efficiency and enabled the bacteria to make the pigment directly from a single nutrient source.

“This project gives a glimpse into a future where biology enables the sustainable production of valuable compounds and materials through advanced automation, data integration and computationally driven design,” said Feist. “Here, we show how we can accelerate innovation in biomanufacturing by bringing together engineers, biologists and chemists using some of the most advanced strain-engineering techniques to develop and optimize a novel product in a relatively short time.”

Record-Breaking Pigment Production

Earlier attempts to make the pigment were notoriously inefficient, typically producing only about five milligrams per liter “if you’re lucky,” said Bushin. The new technique changed that dramatically, increasing output to between one and three grams per liter—a roughly thousandfold improvement.

Although the project required several years of careful planning and trial design, once the experiments began, success came surprisingly quickly.

“It was one of my best days in the lab,” Bushin recalled of the breakthrough moment. “I’d set up the experiment and left it overnight. When I came in the next morning and realized it worked and it was producing a lot of pigment, I was thrilled. Moments like that are why I do science.”

Nature-Inspired Manufacturing for the Future

Moore believes this nature-inspired, non-invasive approach could revolutionize how biochemicals are manufactured.

“We’ve really disrupted the way that people think about how you engineer a cell,” he said. “Our innovative technological approach sparked a huge leap in production capability. This new method solves a supply challenge and could now make this biomaterial much more broadly available.”

From Camouflage to Cosmetics

While some of the potential uses may seem futuristic, interest is already growing among several industries. The U.S. Department of Defense and cosmetics companies are both exploring the material’s potential. Defense researchers are drawn to its natural camouflage ability, while skincare developers are looking into its promise for eco-friendly sunscreens. Other possible applications include color-changing paints, smart coatings, and environmental sensors.

“As we look to the future, humans will want to rethink how we make materials to support our synthetic lifestyle of 8 billion people on Earth,” said Moore. “Thanks to federal funding, we’ve unlocked a promising new pathway for designing nature-inspired materials that are better for people and the planet.”

Reference: “Growth-coupled microbial biosynthesis of the animal pigment xanthommatin” by Leah B. Bushin, Tobias B. Alter, María V. G. Alván-Vargas, Lara Dürr, Elina C. Olson, Mariah J. Avila, Daniel C. Volke, Òscar Puiggené, Taehwan Kim, Leila F. Deravi, Adam M. Feist, Pablo I. Nikel and Bradley S. Moore, 3 November 2025, Nature Biotechnology.

DOI: 10.1038/s41587-025-02867-7

Additional study authors are Tobias Alter, María Alván-Vargas, Daniel Volke, Òscar Puiggené and Pablo Nikel from the Novo Nordisk Foundation Center for Biosustainability; Elina Olson from UC San Diego’s Shu Chien-Gene Lay Department of Bioengineering; Lara Dürr and Mariah Avila from Scripps Institution of Oceanography at UC San Diego; and Taehwan Kim and Leila Deravi from Northeastern University.

Never miss a breakthrough: Join the SciTechDaily newsletter.

Follow us on Google, Discover, and News.