HZB researchers have discovered that highly porous tin foam can mitigate mechanical stress in lithium-ion batteries, making it a promising alternative to conventional graphite electrodes.

Metal-based electrodes in lithium-ion batteries offer significantly higher capacities than traditional graphite electrodes. However, they tend to degrade due to mechanical stress during charging and discharging cycles. Researchers at HZB have demonstrated that a highly porous tin foam can better absorb this stress, improving electrode stability. This discovery positions tin foam as a promising material for lithium-ion batteries.

Conventional lithium-ion batteries typically use multilayer graphite electrodes, paired with cobalt oxide counter electrodes. During charge and discharge cycles, lithium ions migrate into the graphite with minimal volume change, preserving structural integrity. However, graphite’s capacity is limited, driving the search for alternative materials with higher energy storage potential.

Tin as a High-Capacity Electrode Material

Metal-based electrodes, such as aluminum or tin, have the potential to offer higher capacity. However, they tend to expand significantly in volume when lithium is absorbed, which is associated with structural changes and material fatigue. Tin is particularly attractive because its capacity per kilogram is almost three times higher than graphite, and it is not a rare raw material but is available in abundance. One option for realizing metal electrodes that ‘fatigue’ less quickly involves nanostructuring the thin metal foils. Another option is to use porous metal foams.

A team from the Helmholtz-Zentrum Berlin (HZB) has now studied various types of tin electrodes during the discharge and charging process using operando X-ray imaging, and developed an innovative approach to address this problem. Part of the experiments were carried out at the BAMline at BESSY II. The high-resolution radioscopic X-ray images were taken in collaboration with imaging experts Dr. Nikolai Kardjilov and Dr. André Hilger at HZB.

‘This allowed us to track the structural changes in the investigated Sn-metal-based electrodes during the charging/discharging processes,’ says Dr. Bouchra Bouabadi, first author of the study. With battery expert Dr. Sebastian Risse, she explored how the morphology of the tin electrodes changes during operation due to the inhomogeneous absorption of lithium ions.

The Promise of Tin Foam Technology

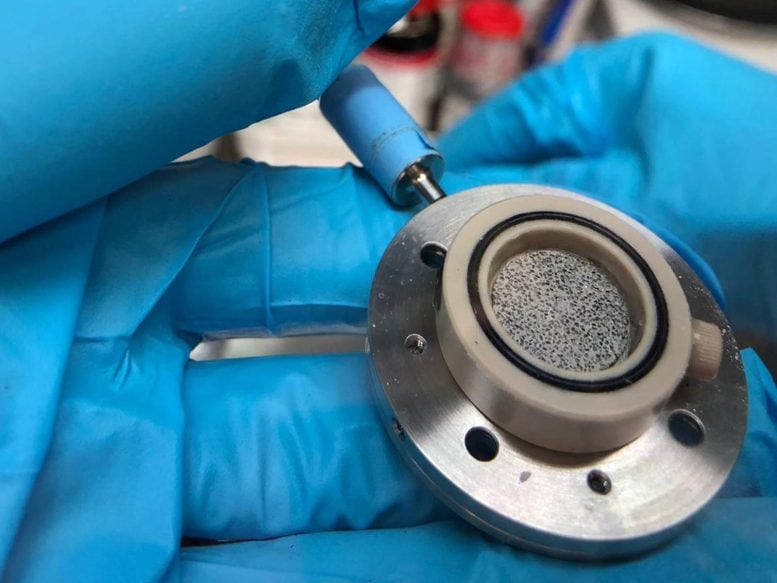

Dr Francisco Garcia-Moreno produced the best version of the tin electrode: a tin foam with countless micrometer-sized pores. ‘We were able to show that the mechanical stress in such a tin foam during volume expansion is significantly reduced,’ says Dr Risse. This makes tin foams an interesting material for lithium batteries.

Garcia-Moreno has already studied numerous metal foams, including those used for components in the automotive industry and aluminum foams for battery electrodes. ‘The tin foams we developed at the TU Berlin are highly porous and a promising alternative to traditional electrode materials,’ he says. The structuring of the tin foams is crucial to reduce mechanical stress as much as possible. Tin foam technology could also be attractive from an economic point of view: ‘Although tin foam is more expensive than conventional tin foil, it offers a cheaper alternative to expensive nanostructuring, while being able to store significantly more lithium ions, thus enabling an increase in capacity.’

Reference: “Morphological Evolution of Sn-Metal-Based Anodes for Lithium-Ion Batteries Using Operando X-Ray Imaging” by Bouchra Bouabadi, André Hilger, Paul H. Kamm, Tillmann R. Neu, Nikolay Kardjilov, Michael Sintschuk, Henning Markötter, Thomas Schedel-Niedrig, Daniel Abou-Ras, Francisco García-Moreno and Sebastian Risse, 17 January 2025, Advanced Science.

DOI: 10.1002/advs.202414892