Researchers have developed a revolutionary neural implant, combining the advantages of surface and deep probing technologies. This transparent, flexible implant with high-density graphene electrodes offers high-resolution data on both surface and deep neural activities. Credit: SciTechDaily.com

A new neural implant revolutionizes brain activity monitoring, combining surface and deep brain data acquisition in a minimally invasive manner.

Scientists at the University of California San Diego have developed a neural implant that provides information about activity deep inside the brain while sitting on its surface. The implant is made up of a thin, transparent and flexible polymer strip that is packed with a dense array of <span class="glossaryLink" aria-describedby="tt" data-cmtooltip="

” data-gt-translate-attributes=”[{"attribute":"data-cmtooltip", "format":"html"}]” tabindex=”0″ role=”link”>graphene electrodes. The technology, tested in transgenic mice, brings the researchers a step closer to building a minimally invasive brain-computer interface (BCI) that provides high-resolution data about deep neural activity by using recordings from the brain surface.

The work will be published today (January 11) in the journal Nature Nanotechnology.

Overcoming Current Limitations in Neural Implants

“We are expanding the spatial reach of neural recordings with this technology,” said study senior author Duygu Kuzum, a professor in the Department of Electrical and Computer Engineering at the UC San Diego Jacobs School of Engineering. “Even though our implant resides on the brain’s surface, its design goes beyond the limits of physical sensing in that it can infer neural activity from deeper layers.”

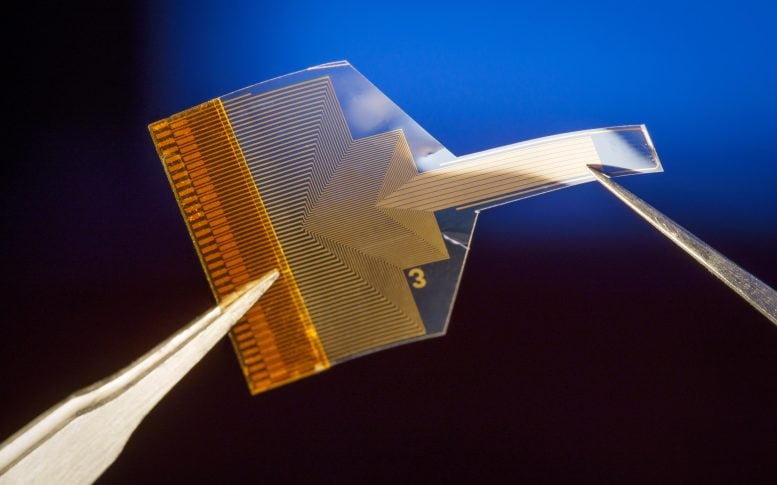

When placed on the surface of the brain, this thin, flexible implant enables researchers to capture high-resolution information about neural activity deep inside the brain without damaging its delicate tissue. Credit: David Baillot/UC San Diego Jacobs School of Engineering

This work overcomes the limitations of current neural implant technologies. Existing surface arrays, for example, are minimally invasive, but they lack the ability to capture information beyond the brain’s outer layers. In contrast, electrode arrays with thin needles that penetrate the brain are capable of probing deeper layers, but they often lead to inflammation and scarring, compromising signal quality over time.

The new neural implant developed at UC San Diego offers the best of both worlds.

Implant Details

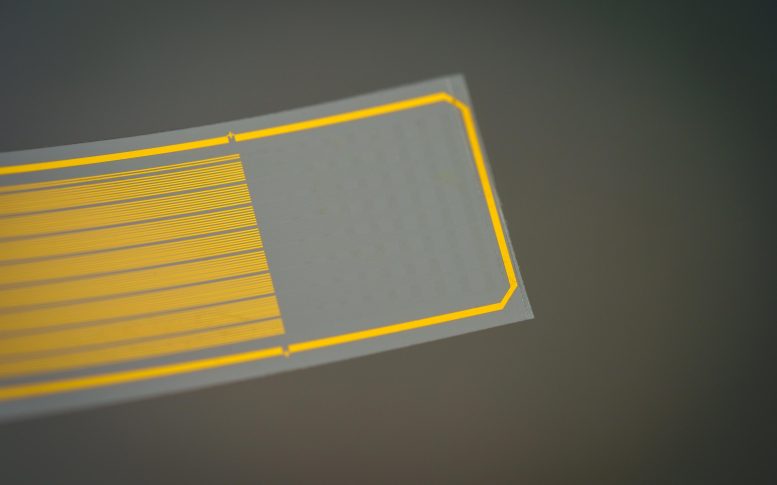

The implant is a thin, transparent, and flexible polymer strip that conforms to the brain’s surface. The strip is embedded with a high-density array of tiny, circular graphene electrodes, each measuring 20 micrometers in diameter. Each electrode is connected by a micrometers-thin graphene wire to a circuit board.

In tests on transgenic mice, the implant enabled the researchers to capture high-resolution information about two types of neural activity–electrical activity and calcium activity–at the same time. When placed on the surface of the brain, the implant recorded electrical signals from neurons in the outer layers. At the same time, the researchers used a two-<span class="glossaryLink" aria-describedby="tt" data-cmtooltip="

” data-gt-translate-attributes=”[{"attribute":"data-cmtooltip", "format":"html"}]” tabindex=”0″ role=”link”>photon microscope to shine laser light through the implant to image calcium spikes from neurons located as deep as 250 micrometers below the surface. The researchers found a correlation between surface electrical signals and calcium spikes in deeper layers. This correlation enabled the researchers to use surface electrical signals to train neural networks to predict calcium activity—not only for large populations of neurons, but also individual neurons—at various depths.

Closeup of the graphene electrode array. Credit: David Baillot/UC San Diego Jacobs School of Engineering

“The neural network model is trained to learn the relationship between the surface electrical recordings and the calcium ion activity of the neurons at depth,” said Kuzum. “Once it learns that relationship, we can use the model to predict the depth activity from the surface.”

An advantage of being able to predict calcium activity from electrical signals is that it overcomes the limitations of imaging experiments. When imaging calcium spikes, the subject’s head must be fixed under a microscope. Also, these experiments can only last for an hour or two at a time.

“Since electrical recordings do not have these limitations, our technology makes it possible to conduct longer duration experiments in which the subject is free to move around and perform complex behavioral tasks,” said study co-first author Mehrdad Ramezani, an electrical and computer engineering Ph.D. student in Kuzum’s lab. “This can provide a more comprehensive understanding of neural activity in dynamic, real-world scenarios.”

Designing and Fabricating the Neural Implant

The technology owes its success to several innovative design features: transparency and high electrode density combined with <span class="glossaryLink" aria-describedby="tt" data-cmtooltip="

” data-gt-translate-attributes=”[{"attribute":"data-cmtooltip", "format":"html"}]” tabindex=”0″ role=”link”>mach ine learning

“This new generation of transparent graphene electrodes embedded at high density enables us to sample neural activity with higher spatial resolution,” said Kuzum. “As a result, the quality of signals improves significantly. What makes this technology even more remarkable is the integration of machine learning methods, which make it possible to predict deep neural activity from surface signals.”

This study was a collaborative effort among multiple research groups at UC San Diego. The team, led by Kuzum, one of the world leaders in developing multimodal neural interfaces, includes nanoengineering professor Ertugrul Cubukcu, who specializes in advanced micro- and nanofabrication techniques for graphene materials; electrical and computer engineering professor Vikash Gilja, whose lab integrates domain-specific knowledge from the fields of basic neuroscience, signal processing, and machine learning to decode neural signals; and neurobiology and neurosciences professor Takaki Komiyama, whose lab focuses on investigating neural circuit mechanisms that underlie flexible behaviors.

Transparency is one of the key features of this neural implant. Traditional implants use opaque metal materials for their electrodes and wires, which block the view of neurons beneath the electrodes during imaging experiments. In contrast, an implant made using graphene is transparent, which provides a completely clear field of view for a microscope during imaging experiments.

“Seamless integration of recording electrical signals and optical imaging of the neural activity at the same time is only possible with this technology,” said Kuzum. “Being able to conduct both experiments at the same time gives us more relevant data because we can see how the imaging experiments are time-coupled to the electrical recordings.”

Key Features and Fabrication Challenges

To make the implant completely transparent, the researchers used super thin, long graphene wires instead of traditional metal wires to connect the electrodes to the circuit board. However, fabricating a single layer of graphene as a thin, long wire is challenging because any defect will render the wire nonfunctional, explained Ramezani. “There may be a gap in the graphene wire that prevents the electrical signal from flowing through, so you basically end up with a broken wire.”

The researchers addressed this issue using a clever technique. Instead of fabricating the wires as a single layer of graphene, they fabricated them as a double layer doped with nitric <span class="glossaryLink" aria-describedby="tt" data-cmtooltip="

” data-gt-translate-attributes=”[{"attribute":"data-cmtooltip", "format":"html"}]” tabindex=”0″ role=”link”>acid in the middle. “By having two layers of graphene on top of one another, there’s a good chance that defects in one layer will be masked by the other layer, ensuring the creation of fully functional, thin and long graphene wires with improved conductivity,” said Ramezani.

According to the researchers, this study demonstrates the most densely packed transparent electrode array on a surface-sitting neural implant to date. Achieving high density required fabricating extremely small graphene electrodes. This presented a considerable challenge, as shrinking graphene electrodes in size increases their impedance—this hinders the flow of electrical current needed for recording neural activity. To overcome this obstacle, the researchers used a microfabrication technique developed by Kuzum’s lab that involves depositing platinum nanoparticles onto the graphene electrodes. This approach significantly improved electron flow through the electrodes while keeping them tiny and transparent.

Looking Ahead: Future Applications and Research

The team will next focus on testing the technology in different animal models, with the ultimate goal of human translation in the future.

Kuzum’s research group is also dedicated to using the technology to advance fundamental neuroscience research. In that spirit, they are sharing the technology with labs across the U.S. and Europe, contributing to diverse studies ranging from understanding how vascular activity is coupled to electrical activity in the brain to investigating how place cells in the brain are so efficient at creating spatial memory. To make this technology more widely available, Kuzum’s team has applied for a <span class="glossaryLink" aria-describedby="tt" data-cmtooltip="

” data-gt-translate-attributes=”[{"attribute":"data-cmtooltip", "format":"html"}]” tabindex=”0″ role=”link”>National Institutes of Health (NIH) grant to fund efforts in scaling up production and facilitating its adoption by researchers worldwide.

“This technology can be used for so many different fundamental neuroscience investigations, and we are eager to do our part to accelerate progress in better understanding the human brain,” said Kuzum.

Reference: “High-density Transparent Graphene Arrays for Predicting Cellular Calcium Activity at Depth from Surface Potential Recordings” by Jeong-Hoon Kim, Xin Liu, Chi Ren, Abdullah Alothman, Chawina De-Eknamkul and Madison N. Wilson, 11 January 2023, Nature Nanotechnology.

DOI: 10.1038/s41565-023-01576-z

This research was supported by the Office of Naval Research (N000142012405, N000142312163 and N000141912545), the National Science Foundation (ECCS-2024776, ECCS-1752241 and ECCS-1734940) and the National Institutes of Health (R21 EY029466, R21 EB026180, DP2 EB030992, R01 NS091010A, R01 EY025349, R01 DC014690, R21 NS109722 AND P30 EY022589), Pew Charitable Trusts, and David and Lucile Packard Foundation. This work was performed in part at the San Diego Nanotechnology Infrastructure (SDNI) at UC San Diego, a member of the National Nanotechnology Coordinated Infrastructure, which is supported by the National Science Foundation (grant ECCS-1542148).