Engineers at RMIT University have developed a new 3D-printed titanium material that costs roughly one-third less than standard titanium alloys.

Researchers at RMIT University in Australia have developed a new form of titanium for 3D printing that costs approximately 33% less than the titanium alloys currently in widespread use.

Replacing expensive elements

The researchers substituted vanadium, which has become increasingly costly, with more affordable and widely available alternative elements.

Their novel method has been detailed in <span class="glossaryLink" aria-describedby="tt" data-cmtooltip="

” data-gt-translate-attributes=”[{"attribute":"data-cmtooltip", "format":"html"}]” tabindex=”0″ role=”link”>Nature Communications, and RMIT has submitted a provisional patent as the team explores commercial possibilities for using the <span class="glossaryLink" aria-describedby="tt" data-cmtooltip="

” data-gt-translate-attributes=”[{"attribute":"data-cmtooltip", "format":"html"}]” tabindex=”0″ role=”link”>alloy in sectors such as aerospace and medical devices.

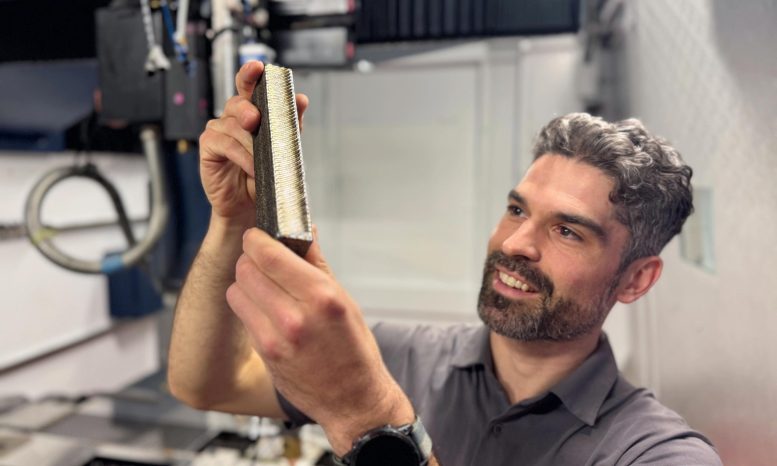

According to Ryan Brooke, a PhD candidate at RMIT’s Centre for Additive Manufacturing (RCAM) and lead author of the study, the new alloy demonstrated enhanced strength and performance when compared to conventional 3D-printed titanium alloys (Ti-6Al-4V).

Brooke, who recently received a Research Translation Fellowship at RMIT to focus on advancing the technology toward commercial use, noted that the field of 3D-printed titanium alloys is primed for breakthrough developments.

“3D printing allows faster, less wasteful, and more tailorable production yet we’re still relying on legacy alloys like Ti-6Al-4V that doesn’t allow full capitalization of this potential. It’s like we’ve created an airplane and are still just driving it around the streets,” he said.

“New types of titanium and other alloys will allow us to really push the boundaries of what’s possible with 3D printing and the framework for designing new alloys outlined in our study is a significant step in that direction.”

A new design approach

The new study presents an efficient method for choosing alloying elements that reduces both time and cost, while leveraging the benefits of advanced 3D-printing techniques.

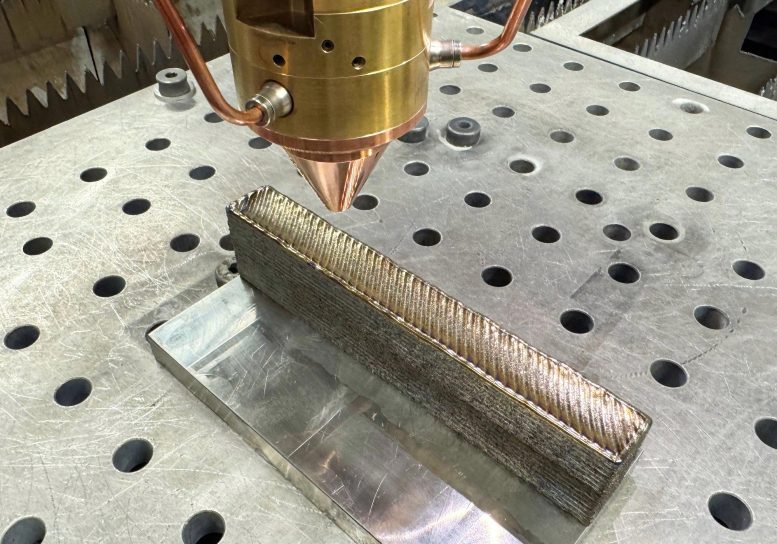

It also introduces an improved model for predicting the grain structure of metals produced through additive manufacturing.

Using this approach, the team developed a titanium alloy—details of which are withheld for commercial considerations—that is 29% less expensive to produce than conventional titanium.

Through this design framework, the metal also prints more evenly, avoiding the column-shaped microstructures that lead to uneven mechanical properties in some 3D printed alloys.

“By developing a more cost-effective formula that avoids this columnar microstructure, we have solved two key challenges preventing widespread adoption of 3D printing,” said Brooke, who recently completed market validation as part of <span class="glossaryLink" aria-describedby="tt" data-cmtooltip="

<div class="text-gray-400 flex self-end lg:self-center justify-center mt-2 gap-4 lg:gap-1 lg:absolute lg:top-0 lg:translate-x-full lg:right-0 lg:mt-0 lg:pl-2 visible"> </div>

” data-gt-translate-attributes=”[{"attribute":"data-cmtooltip", "format":"html"}]” tabindex=”0″ role=”link”>CSIRO’s ON Prime program talking to aerospace, automotive, and MedTech industry representatives about their needs.

Market feedback and next steps

“What I heard loud and clear from end users was that to bring new alloys to market, the benefits have to not just be minor incremental steps but a full leap forward, and that’s what we have achieved here,” he said.

“We have been able to not only produce titanium alloys with a uniform grain structure, but with reduced costs, while also making it stronger and more ductile.”

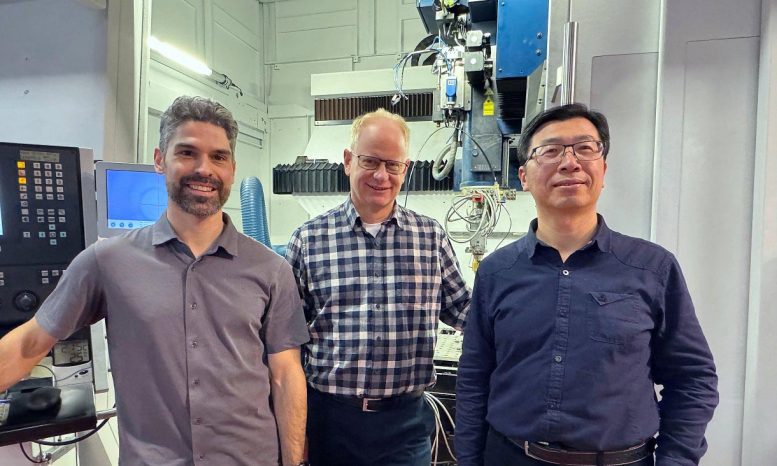

Study corresponding author Professor Mark Easton said RCAM was focused on creating new collaborations to further develop the technology.

“We are very excited about the prospects of this new alloy, but it requires a team from across the supply chain to make it successful. So, we are looking for partners to provide guidance for the next stages of development,” he said.

Samples were produced and tested at RMIT’s cutting-edge Advanced Manufacturing Precinct.

Reference: “Compositional criteria to predict columnar to equiaxed transitions in metal additive manufacturing” by Ryan Brooke, Duyao Zhang, Dong Qiu, Mark A. Gibson and Mark Easton, 31 June 2025, Nature Communications.

DOI: 10.1038/s41467-025-60162-0

Never miss a breakthrough: Join the SciTechDaily newsletter.