Innovative high-entropy alloys, crafted through laser-based additive manufacturing, offer unprecedented strength and ductility for industrial applications. These new materials, analyzed with advanced techniques, promise enhanced performance in extreme conditions. Credit: SciTechDaily.com

Laser-based additive manufacturing produces high-entropy alloys that are stronger and less likely to fracture.

Researchers make a type of material called durable high-entropy alloys (HEAs) by combining several elemental metals. HEAs have potential uses in applications involving severe wear and tear, extreme temperatures, radiation, and high stress.

They can be made using 3D printing, also known as additive manufacturing (AM), but this usually results in poor ductility. This means 3D-printed HEAs are difficult to shape and do not deform, or stretch, enough under loads to prevent fractures.

Scientists have now used laser-based AM to form HEAs that are stronger and much more ductile. They used neutron and X-ray scattering and electron microscopy to better understand the mechanisms of these performance improvements.

Potential Industrial Applications and Energy Efficiency

Industry could one day use stronger and more easily shaped HEAs in manufacturing. To work in these applications, light and complex HEA parts need improved durability, reliability, and resistance to fracturing.

This would benefit consumers and industry, for example, by enabling the production of safer and more fuel-efficient vehicles, stronger products, and longer-lasting machinery. In addition, laser-based AM, in which lasers fuse powdered alloys into solid metal shapes, is highly energy efficient. This makes it attractive for producing new types of HEAs.

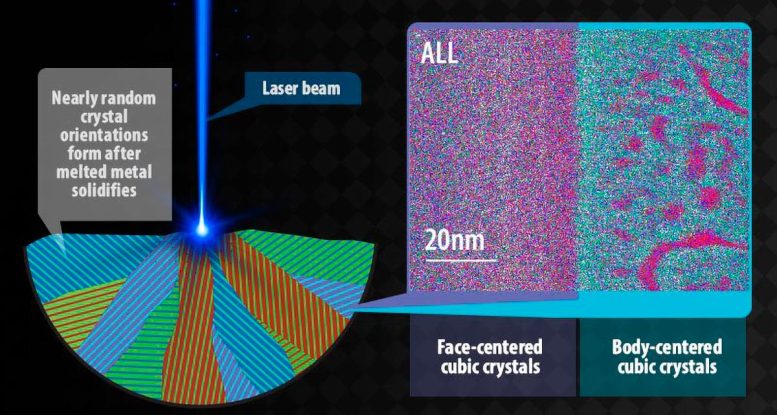

Images of the two crystal structures (right) found in a high-entropy alloy (left) made by additive manufacturing. Credit: University of Massachusetts Amherst

Nano-Lamellae Structure and Mechanical Properties

The laser-based AM process produced nanometer-thick nano-lamellae (thin layers of plates) offering high strength, while the plates’ distinct edges permit a degree of slippage (ductility). The plates consist of alternating layers of face-centered cubic (FCC) crystal structures that average approximately 150 nanometers thick and body-centered cubic (BCC) crystal structures that average approximately 65 nanometers thick.

The new HEAs exhibited high yield strengths of about 1.3 gigapascals – exceeding the strongest titanium alloys. These HEAs also offer an elongation of about 14%, which is higher than other AM metal alloys given the same yield strength. Elongation is a measure of how much bending a material can withstand without breaking.

Advanced Research Techniques and Facilities

Neutron data from the Spallation Neutron Source, a Department of Energy (DOE) Office of Science user facility at Oak Ridge National Laboratory (ORNL), enabled the researchers to examine the interior mechanical load sharing of the HEA samples while under strain.

The researchers used an <span class="glossaryLink" aria-describedby="tt" data-cmtooltip="

” data-gt-translate-attributes=”[{"attribute":"data-cmtooltip", "format":"html"}]” tabindex=”0″ role=”link”>atom probe instrument at the Center for Nanophase Materials Sciences, also a DOE user facility at ORNL, to capture detailed 3D images of the compositions and microstructures, consisting of alternating nano-lamellae layers.

The phases of different annealed samples were studied using X-ray diffraction at the Advanced Photon Source, another DOE Office of Science user facility at Argonne National Laboratory.

Reference: “Strong yet ductile nanolamellar high-entropy alloys by additive manufacturing” by Jie Ren, Yin Zhang, Dexin Zhao, Yan Chen, Shuai Guan, Yanfang Liu, Liang Liu, Siyuan Peng, Fanyue Kong, Jonathan D. Poplawsky, Guanhui Gao, Thomas Voisin, Ke An, Y. Morris Wang, Kelvin Y. Xie, Ting Zhu and Wen Chen, 3 August 2022, Nature.

DOI: 10.1038/s41586-022-04914-8

This research was performed at the Spallation Neutron Source, the Advanced Photon Source, and Center for Nanophase Materials Sciences, all of which are DOE Office of Science user facilities. Funding support for this work included the National Science Foundation, the University of Massachusetts Amherst, and the Laboratory Directed Research and Development program at Lawrence Livermore National Laboratory.