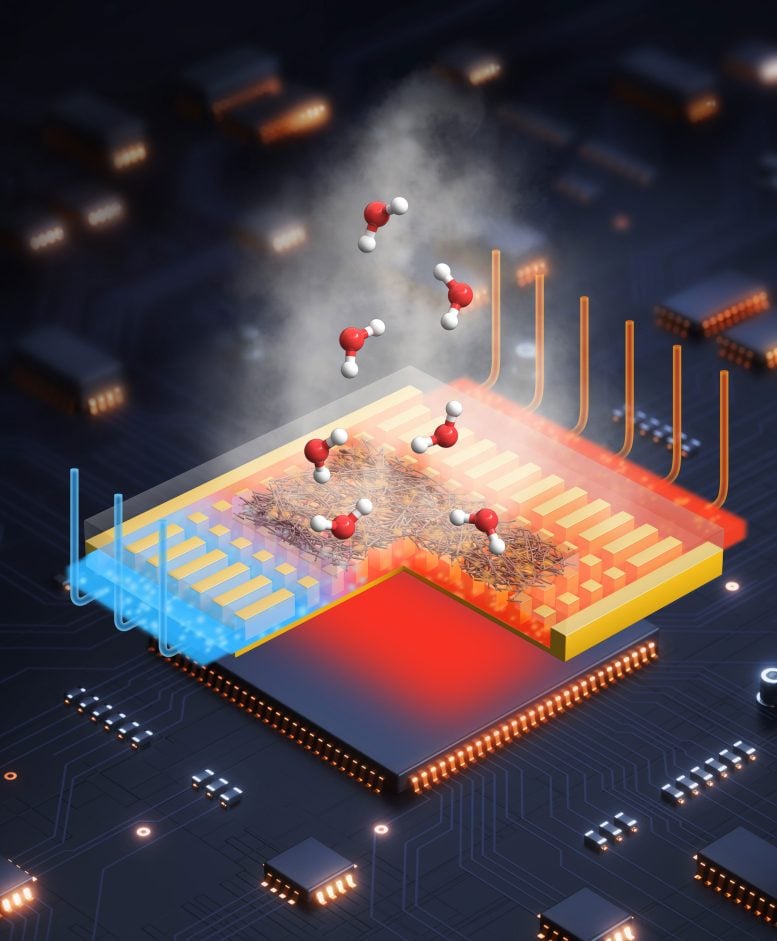

Engineers have developed a passive evaporative cooling membrane that dramatically improves heat removal for electronics and data centers

Engineers at the University of California San Diego have created an innovative cooling system designed to greatly enhance the energy efficiency of data centers and high-performance electronic devices. This new approach relies on a specially engineered fiber membr ane that naturally removes heat through evaporation. It provides an effective and energy-saving alternative to conventional cooling methods such as fans, heat sinks, and liquid pumps, while also potentially reducing the large amounts of water used by many existing systems.

The breakthrough is described in detail in a study published in the journal Joule.

As artificial intelligence (AI) and cloud computing continue to grow, so does the demand for data processing, and the heat that accompanies it. Cooling now represents as much as 40% of a data center’s total energy consumption. If current growth continues, global energy demand for cooling could more than double by 2030.

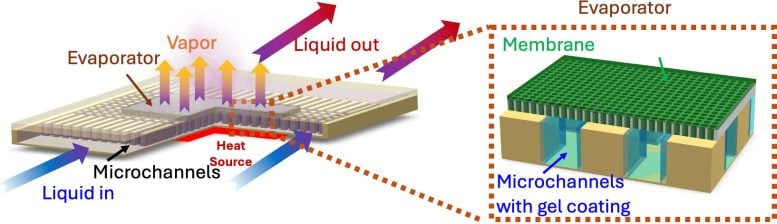

The newly developed evaporative cooling system may help slow this trend. It operates using an inexpensive fiber membrane made up of countless interconnected microscopic pores that draw cooling liquid across its surface through capillary action. When the liquid evaporates, it removes heat from the underlying electronics without the need for additional energy. The membrane is placed above microchannels that supply the liquid, allowing heat to dissipate efficiently from the components below.

Harnessing Evaporation for Efficient Heat Dissipation

“Compared to traditional air or liquid cooling, evaporation can dissipate higher heat flux while using less energy,” said Renkun Chen, professor in the Department of Mechanical and Aerospace Engineering at the UC San Diego Jacobs School of Engineering, who co-led the project with professors Shengqiang Cai and Abhishek Saha, both from the same department. Mechanical and aerospace engineering Ph.D. student Tianshi Feng and postdoctoral researcher Yu Pei, both members of Chen’s research group, are co-first authors on the study.

Many applications currently rely on evaporation for cooling. Heat pipes in laptops and evaporators in air conditioners are some examples, explained Chen. But applying it effectively to high-power electronics has been a challenge.

Previous attempts using porous membranes—which have large surface areas ideal for evaporation—failed because the pores were often either too small, causing clogging, or too large, leading to unwanted boiling.

“Here, we use porous fiber membranes with interconnected pores with the right size,” said Chen. This design achieves efficient evaporation without those downsides.

Record-Breaking Performance and Future Potential

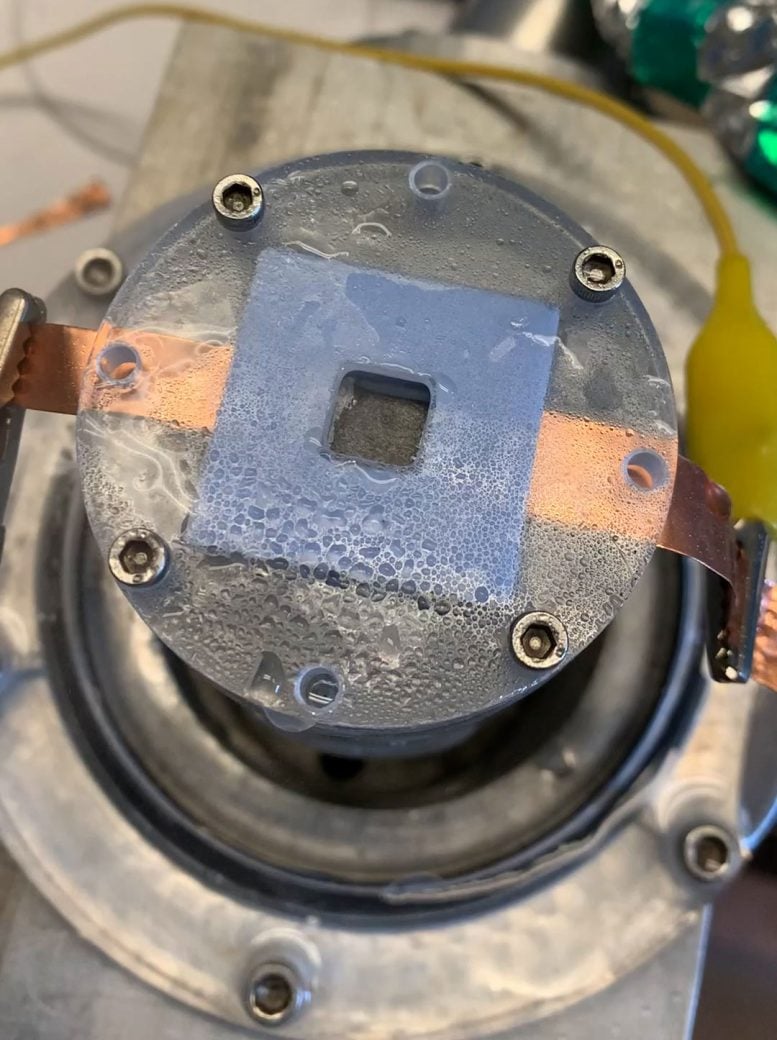

When tested across variable heat fluxes, the membrane achieved record-breaking performance. It managed heat fluxes exceeding 800 watts of heat per square centimeter—one of the highest levels ever recorded for this kind of cooling system. It also proved stable over multiple hours of operation.

“This success showcases the potential of reimagining materials for entirely new applications,” said Chen. “These fiber membranes were originally designed for filtration, and no one had previously explored their use in evaporation. We recognized that their unique structural characteristics—interconnected pores and just the right pore size—could make them ideal for efficient evaporative cooling. What surprised us was that, with the right mechanical reinforcement, they not only withstood the high heat flux–they performed extremely well under it.”

While the current results are promising, Chen says the technology is still operating well below its theoretical limit. The team is now working to refine the membrane and optimize performance. Next steps include integrating it into prototypes of cold plates, which are flat components that attach to chips like CPUs and GPUs to dissipate heat. The team is also launching a startup company to commercialize the technology.

Reference: “High-flux and stable thin-film evaporation from fiber membranes with interconnected pores” by Tianshi Feng, Yu Pei, Haowen Zhang, Brooklyn Asai, Gaoweiang Dong, Atharva Joshi, Abhishek Saha, Shengqiang Cai and Renkun Chen, 13 June 2025, Joule.

DOI: 10.1016/j.joule.2025.101975

This research was supported by the National Science Foundation (grants CMMI-1762560 and DMR-2005181). The work was performed in part at the San Diego Nanotechnology Infrastructure (SDNI) at UC San Diego, a member of the National Nanotechnology Coordinated Infrastructure, which is supported by the National Science Foundation (grant ECCS-2025752).

Disclosures: A patent related to this work was filed by the Regents of the University of California (PCT Application No. PCT/US24/46923.). The authors declare that they have no other competing interests.

Never miss a breakthrough: Join the SciTechDaily newsletter.

Follow us on Google, Discover, and News.