AI-designed materials cool better than paint and save energy. Their uses span homes, clothes, and space tech.

A new class of materials created with the help of <span class="glossaryLink" aria-describedby="tt" data-cmtooltip="

” data-gt-translate-attributes=”[{"attribute":"data-cmtooltip", "format":"html"}]” tabindex=”0″ role=”link”>artificial intelligence and <span class="glossaryLink" aria-describedby="tt" data-cmtooltip="

” data-gt-translate-attributes=”[{"attribute":"data-cmtooltip", "format":"html"}]” tabindex=”0″ role=”link”>machine learning could help lower indoor temperatures and reduce energy costs.

Scientists from the University of Texas at Austin, along with collaborators from Shanghai Jiao Tong University, the National University of Singapore, and Umea University in Sweden, designed a machine learning method to engineer complex, three-dimensional thermal meta-emitters. With this framework, they generated over 1,500 unique materials capable of selectively emitting heat in controlled ways, offering greater precision in heating and cooling for improved energy efficiency.

“Our machine learning framework represents a significant leap forward in the design of thermal meta-emitters,” said Yuebing Zheng, professor in the Cockrell School of Engineering’s Walker Department of Mechanical Engineering and co-leader of the study published in Nature. “By automating the process and expanding the design space, we can create materials with superior performance that were previously unimaginable.”

Cooling tests show dramatic energy savings

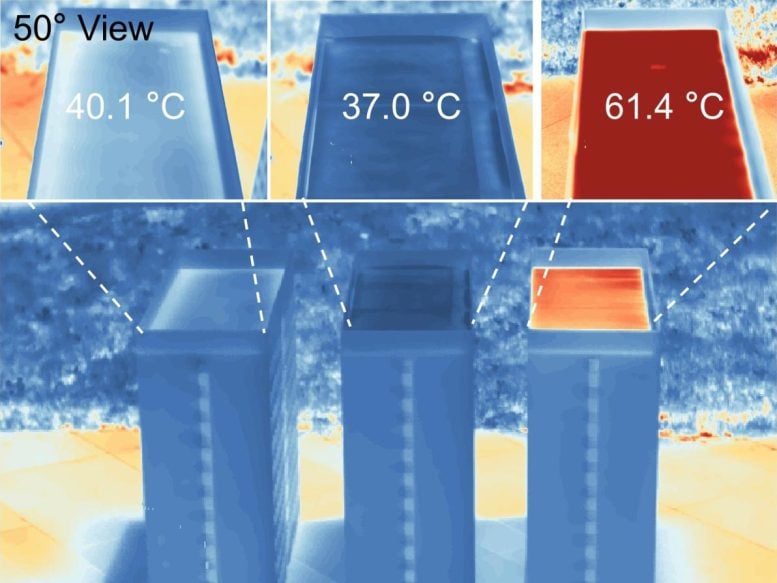

To evaluate their design system, the researchers manufactured four sample materials and tested their performance. One of these materials was applied to the roof of a model house and compared with standard commercial white and gray paints to assess its cooling ability. After four hours of direct midday sunlight, the roof coated with the meta-emitter material was, on average, 5 to 20 degrees <span class="glossaryLink" aria-describedby="tt" data-cmtooltip="

” data-gt-translate-attributes=”[{"attribute":"data-cmtooltip", "format":"html"}]” tabindex=”0″ role=”link”>Celsius cooler than those coated with the conventional paints.

Based on this performance, the team estimated that such cooling could save around 15,800 kilowatt-hours annually in an apartment building located in a hot city like Rio de Janeiro or Bangkok. For context, a standard air conditioning unit typically consumes about 1,500 kilowatt-hours per year.

The potential uses for these materials extend far beyond residential and commercial energy savings. Through the same machine learning approach, the team created seven categories of meta-emitters, each tailored to specific functions.

These materials could be used in cities to help lower urban temperatures by reflecting sunlight and releasing heat at targeted wavelengths, potentially reducing the urban heat island effect caused by dense concrete structures and limited greenery. They could also be employed in space applications to help regulate spacecraft temperatures by efficiently managing both incoming solar radiation and emitted heat.

Consumer applications in textiles and vehicles

Beyond the applications in this research, thermal meta-emitters could become a part of many things we use daily. Integrating them into textiles and fabrics could improve cooling technology in clothing and outdoor equipment. Wrapping cars with them and embedding them into interior materials could reduce the heat that builds up when they sit in the sun.

The painstaking traditional process of designing these materials has held them back from mainstream adoption. Other automated options struggle to deal with the complexity in the three-dimensional hierarchical structure of the meta-emitters, limiting the outcomes to simple geometries such as thin-film stacks or planar patterns with the performance coming in short on some measures.

“Traditionally, designing these materials has been slow and labor-intensive, relying on trial-and-error methods,” said Zheng. “This approach often leads to suboptimal designs and limits the ability to create materials with the necessary properties to be effective.”

The researchers will continue to refine this technology and apply it to more aspects of their field of nanophotonics – the interaction of light and matter at the tiniest scales.

“Machine learning may not be the solution to everything, but the unique spectral requirements of thermal management make it particularly suitable for designing high-performance thermal emitters,” said Kan Yao, a co-author of this work and a research fellow in Zheng’s group.

Reference: “Ultrabroadband and band-selective thermal meta-emitters by machine learning” by Chengyu Xiao, Mengqi Liu, Kan Yao, Yifan Zhang, Mengqi Zhang, Max Yan, Ya Sun, Xianghui Liu, Xuanyu Cui, Tongxiang Fan, Changying Zhao, Wansu Hua, Yinqiao Ying, Yuebing Zheng, Di Zhang, Cheng-Wei Qiu and Han Zhou, 2 July 2025, Nature.

DOI: 10.1038/s41586-025-09102-y

Never miss a breakthrough: Join the SciTechDaily newsletter.