The world’s energy demand is rising, and NREL’s ULIS power module could help meet it.

Demand for energy worldwide is climbing rapidly, driven in part by power hungry data centers that support artificial intelligence and by growth in manufacturing. Meeting these expanding energy needs is becoming an urgent global challenge.

One promising strategy is to use existing electricity more efficiently and at lower cost. Working toward that goal, researchers at NREL have developed a new silicon carbide-based power module. This component, which houses the electronics that regulate how electricity moves between systems, delivers levels of efficiency, power density, and manufacturability that have not been achieved before.

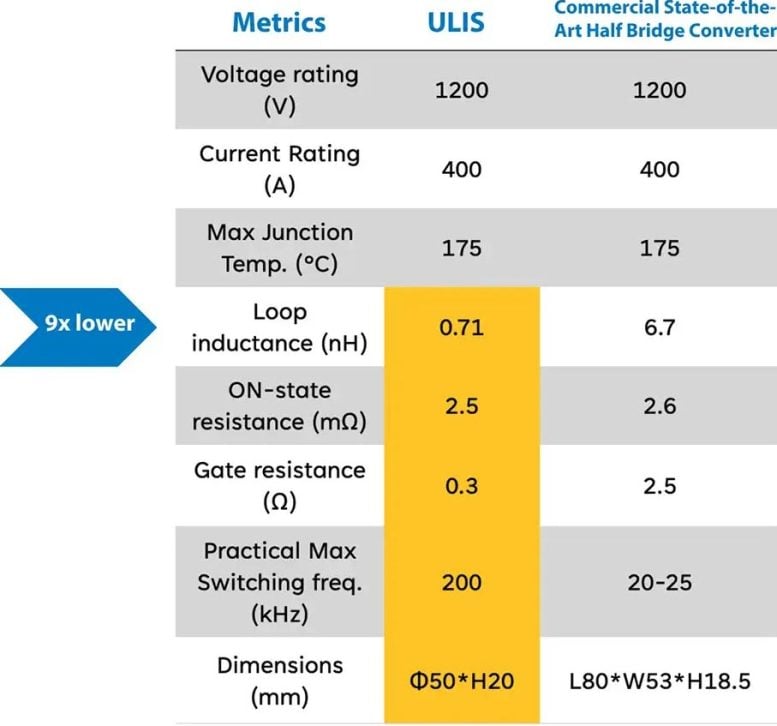

The new technology is known as NREL’s Ultra-Low Inductance Smart power module, or ULIS. Built around silicon carbide semiconductors, ULIS can deliver five times the energy density of earlier designs while occupying a smaller footprint. This opens the door for manufacturers to create equipment that is more compact, lighter, and more energy efficient. Rated at 1200 volts and 400 amps, the module is designed for demanding uses, including data centers, electric grids, microreactors, and heavy-duty platforms such as next-generation aircraft and military vehicles.

A key advantage of ULIS is its exceptionally low parasitic inductance, which refers to resistance that limits how quickly electrical current can change. This resistance is one of the main obstacles in power conversion. ULIS reduces parasitic inductance by a factor of seven to nine compared with current leading silicon carbide power modules. Because it can switch electrical current extremely quickly and efficiently, the module is able to extract more usable power from the same electricity supply, making it a strong candidate for addressing rising energy demand.

“We consider ULIS to be a true breakthrough,” said Faisal Khan, NREL’s chief power electronics researcher and the princip al investigator for the project. “It’s a future-proofed, ultrafast power module that will make the next generation of power converters more affordable, efficient, and compact.”

Khan also noted that ULIS is especially well-suited for high stress environments such as aviation and military systems. In addition to being powerful and lightweight, the module continuously tracks its own condition and can anticipate component failures before they happen. For aircraft operating at 30,000 feet above sea level or military vehicles deployed in combat zones, this level of reliability can be critical.

“ULIS was a truly organic effort, built entirely in-house here at NREL,” Khan said. “We are very excited to demonstrate its strengths in real-world settings.”

ULIS Features Entirely New, Low-Cost Design

Many of ULIS’ features are made possible by its wholly new design.

Unlike typical power modules, which assemble semiconductor devices inside a brick-like package, ULIS winds its circuits around a flat, octagonal design. The disk-like shape allows more devices to be housed in a smaller area, making the overall package smaller and lighter. At the same time, novel current routing allows for maximum magnetic flux cancellation, contributing to the power module’s clean, low-loss electrical output—in other words, its ultrahigh efficiency.

“Our biggest concern was that the device switches off and on very quickly, and we needed a layout that wouldn’t create a chokepoint within the design,” said Shuofeng Zhao, an NREL power electronics researcher who designed ULIS’ flux cancellation architecture.

One of the original layouts, Zhao said, looked like a flower with a semiconductor at the tip of each petal. Another idea was to create a hollow cylinder with components wired to the inside. Every idea the team came up with was either too expensive or too difficult to fabricate—until they stopped thinking in three dimensions and flattened the design into nearly two. Sarwar Islam, another NREL power electronics researcher on the ULIS team, came up with the 2D structure, which made it possible to build the module balancing complexity with cost and performance.

“We squished it flat, like a pancake,” Zhao said, “and suddenly we had a low-cost, high-performing design that was much easier to fabricate.”

Another NREL power electronics researcher, Joshua Major, ideated several fabrication innovations to build ULIS’ intricate architecture inexpensively using only NREL tools and lab facilities.

The fine balance the team found between the high electrical performance of a 3D design and a flat, fabrication-friendly layout unlocked ULIS’ full potential.

Second, where conventional power modules rely on bulky and inflexible materials, ULIS takes a new approach.

Traditional designs call for power modules to conduct electricity and dissipate excess heat by bonding copper sheets directly to a ceramic base—an effective, but rigid, solution. ULIS bonds copper to a flexible polymer, called Temprion, to create a thinner, lighter, more configurable design.

Because the material bonds easily to copper using just pressure and heat, and because its parts can be machined using widely available equipment, ULIS can be fabricated quickly and inexpensively. Manufacturing costs total hundreds, rather than thousands, of dollars.

A third breakthrough allows ULIS to function wirelessly, as an isolated unit that can be controlled and monitored without external cables. That modular, Lego-like nature means it can slot into machines as different as data center servers, advanced aircraft, and military vehicles. The patent for this low-latency wireless communication protocol, spearheaded by NREL power electronics Sarwar Islam, is pending.

Finally, while the silicon carbide semiconductors powering ULIS represent the current state of the art, the ULIS research team has intentionally “future-proofed” the design. ULIS can scale to accommodate advancements in semiconductor devices using silicon carbide, gallium nitride, and even gallium oxide, a promising avenue that has not yet been commercialized.

Each innovation adds to a single idea: that in a world where we rely on steady access to electricity, ULIS provides reliability.

ULIS’ Intentional Design for High-Intensity Applications Is Poised for Impact

Where could ULIS make an impact?

- Modernizing the U.S. power grid: Electricity entering the power grid must be converted into a form that can be used by homes, businesses, and industry. Today, this conversion often depends on large, low-frequency transformers and dedicated conversion facilities. ULIS uses extremely fast and efficient switching to deliver more usable energy to consumers. Its ability to operate at high temperatures could also reduce upkeep and maintenance expenses over the lifetime of a power plant.

- Enabling advanced aircraft: Because ULIS can move electricity more quickly than existing technologies while wasting less energy, it supports the development of compact, lightweight, and high-performance power converters for next-generation aircraft. This capability could help emerging designs such as electric vertical takeoff and landing (eVTOL) vehicles, sometimes referred to as “flying taxis,” reach the efficiency and affordability needed for commercial deployment.

- Powering cities and data centers through fusion: Although commercial fusion power remains a future goal, these systems could transform energy delivery in locations where traditional infrastructure is difficult to construct or maintain. With its ultralow inductance and compact, dependable design, ULIS could enable the pulsed power components required for future fusion-based energy systems.

Never miss a breakthrough: Join the SciTechDaily newsletter.

Follow us on Google and Google News.